Aerogel is one of the strangest materials on Earth. It looks like frozen smoke. It feels like air but can hold weight. People use it in space, in homes, and even in clothes. Let’s look at what aerogel is, how it works, and where it is useful.

Aerogel is a solid filled with air. It is made from a gel. A gel is like jelly. The jelly has liquid inside. In aerogel, that liquid is taken out. Air takes its place.

The solid part stays in place like a sponge. This creates a light, dry material that feels almost empty.

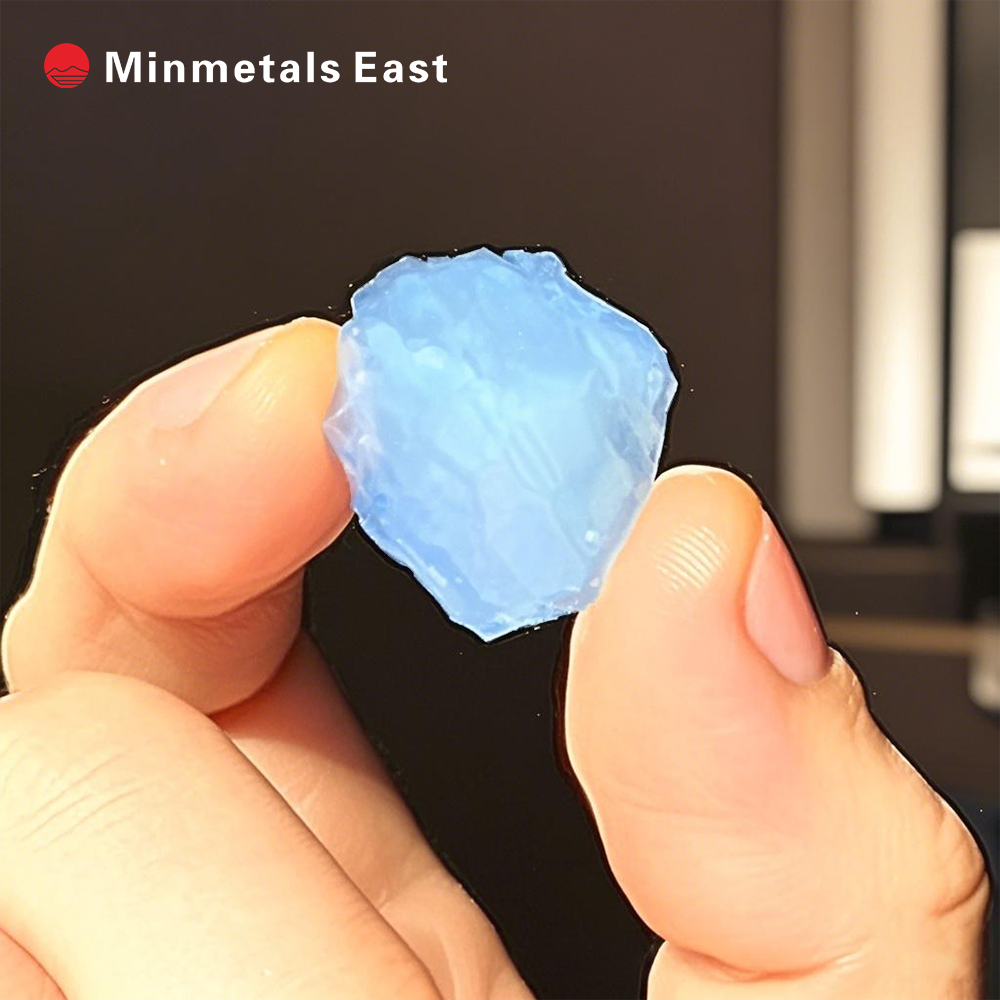

Aerogel is usually pale blue or white. Some aerogels look clear. Some look cloudy. You can touch it, but it can break if squeezed hard. It feels dry and soft like foam but is more fragile.

There are many types of aerogel. Each has different uses. Some common types are:

| Type of Aerogel | Main Material | Main Use | Key Feature |

|---|---|---|---|

| Silica Aerogel | Silicon dioxide (sand-like) | Insulation, lightweight panels, space tech | Very light and blocks heat |

| Carbon Aerogel | Carbon | Batteries, capacitors, energy storage | Stores electricity, light but strong |

| Polymer Aerogel | Flexible polymers (plastic-like) | Clothing, padding, lightweight tools | Soft and flexible, good insulator |

| Metal Oxide Aerogel | Metal oxides (e.g. iron, copper) | Catalysts, gas sensors, science labs | Reacts with gases, strong under heat |

Aerogel is famous for its lightness and strength. It has special physical traits that no other material has.

Main Physical Traits

| Property | Typical Range or Value |

|---|---|

| Density | 0.001–0.5 g/cm³ |

| Porosity (empty space) | 90–99.8% |

| Surface Area | 500–1200 m²/g |

| Thermal Conductivity | 0.013–0.02 W/m·K |

| Sound Absorption | Up to 40 decibels (with panels) |

| Optical Appearance | Translucent or semi-clear |

| Weight | 3x lighter than air (volume-based) |

| Compressive Strength | ~0.1–1.0 MPa |

What These Mean:

Aerogel is not just physically special. It also has chemical traits that affect how it reacts with the world.

| Property | Silica Aerogel |

|---|---|

| Main Element | Silicon dioxide (SiO₂) |

| Reactivity with Water | Weakens or breaks in moisture |

| Acid Resistance | Weak |

| Base Resistance | Weak |

| pH Level | Neutral (about 7) |

| Fire Safety | Will not catch fire |

| Oxidation Stability | Very stable in air |

| Lifespan in Dry Air | Many years |

Meaning:

So, people use it mostly in dry, controlled areas.

.png)

Aerogel is made from a wet gel, which is a jelly-like material filled with liquid. The goal is to remove the liquid gently, leaving only the solid structure filled with air. If dried too fast or without care, the gel will collapse and break. To avoid that, a special process is used:

First, a liquid solution is prepared. For silica aerogel, a liquid called tetraethyl orthosilicate (TEOS) is mixed with water, alcohol, and an acid or base. The acid or base starts a chemical reaction. This reaction makes a jelly-like structure, called a gel.

Inside the gel, there is a solid network of silicon dioxide and liquid filling the tiny spaces. The liquid helps hold the shape while the network forms. This gel is soft and wet at this stage.

The wet gel is left for a certain time, called aging. During this time, the structure becomes stronger. The molecules inside form more bonds, so the gel can handle the next steps. Without aging, the gel might break during drying. Aging can take several hours to a few days, depending on the size and type of gel.

After aging, the liquid inside the gel needs to be changed. The original liquid (water or alcohol) can cause damage during drying because of surface tension. To fix this, the gel is soaked in a different liquid, like ethanol or liquid carbon dioxide.

This step is called solvent exchange. It replaces the original liquid with a liquid that can be removed safely in the next step. The gel is placed in a bath of the new liquid for several hours or days.

The gel filled with the new liquid is put into a sealed chamber. The chamber is heated and pressurized. As pressure and temperature rise, the liquid inside the gel becomes a supercritical fluid.

A supercritical fluid is special. It has no surface tension, so it does not pull on the gel network. This prevents the fragile structure from breaking. The temperature and pressure used depend on the solvent:

Once the supercritical fluid forms, the pressure inside the chamber is slowly reduced. The supercritical fluid turns into gas and escapes, leaving behind the dry gel structure. This keeps the aerogel light and airy.

After supercritical drying, the chamber returns to normal pressure and temperature. The aerogel cools down and finishes drying. Now it becomes a solid structure with tiny air pockets inside. It is light, strong, and ready to use.

Note:

Aerogel is more than just a lab material. It is used in many industries and products because it blocks heat, reduces sound, and weighs almost nothing.

Aerogel felt stop heat from passing through walls and windows. This makes homes and buildings warmer in winter and cooler in summer. It also reduces outside noise.

Examples include:

The result is lower energy use, better comfort, and quieter spaces.

NASA first used aerogel in 1999 during the Stardust mission to catch space dust. Now, aerogel helps with:

Aerogel is chosen because it is light but strong. It reduces the weight of rockets, which saves fuel and cost.

Aerogel can clean up oil spills by absorbing oil while repelling water. It also supports green technology.

Uses include:

These uses help save energy, protect the environment, and lower carbon emissions.

Aerogel has found its way into daily products and creative designs:

Aerogel’s unique mix of lightness, strength, and insulation makes it useful for many real-world jobs.

Aerogel is still costly:

| Type of Aerogel | Price |

|---|---|

| Silica Aerogel Sheet | $400–$700 per square meter |

| Aerogel Blanket (roll) | $100–$200 per square meter |

| Small Lab Sample (5g) | $50–$100 per piece |

| Carbon Aerogel (special) | $300–$1000 per gram (for labs) |

Aerogel is a smart, strange, and useful material. It keeps heat in, blocks sound, and floats in your hand. From space tools to home walls, it solves many problems. The price is high, but the value is clear.

Q1: Is aerogel safe for people to handle?

Yes, aerogel is generally safe to touch. However, silica aerogel can release tiny dust particles if handled roughly, which can irritate skin, eyes, or lungs. It’s best to wear gloves and a mask when handling large amounts of aerogel.

Q2: Can aerogel be used in food or medicine?

No, aerogel is not used in food or medicine. Its chemical makeup (especially silica aerogel) is not approved for direct contact with the human body. It can absorb oils and moisture, which makes it unsafe for ingestion or medical use.

Q3: How does aerogel compare to traditional insulation materials?

Aerogel insulates much better than materials like fiberglass or foam per thickness. For example, a 1-centimeter thick aerogel panel can block as much heat as 3–4 centimeters of fiberglass. This allows for thinner insulation layers in buildings or equipment.

Q4: What happens to aerogel in humid environments?

Silica aerogel absorbs moisture from the air, which can weaken its structure over time. In high humidity, it can break down and lose its insulating properties. That’s why aerogel panels used in construction are often covered with protective films.

Q5: Is aerogel environmentally friendly to produce and dispose of?

Aerogel production uses chemicals and energy, so it has an environmental cost. However, aerogel can help lower energy use in homes and industry, which reduces carbon emissions. It is non-toxic and inert after disposal, but silica dust can be harmful to ecosystems if released in large amounts.